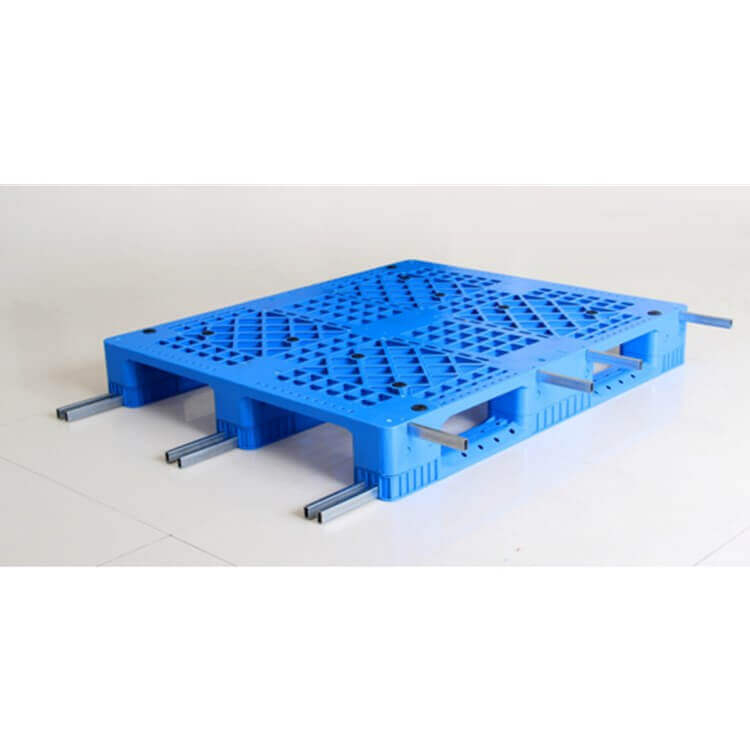

Wholesale Turnover Plastic Pallet

Turnover plastic pallets, also known as reversible plastic pallets or two-way entry plastic pallets, are a type of pallet designed for the efficient storage and transportation of goods and materials. These pallets are called “turnover” because they are intended to be used in a two-way entry system, meaning forklifts or pallet jacks can enter and lift the pallet from two opposite sides, making them versatile and easy to handle.

Advantages

Two-Way Entry: Turnover plastic pallets have entry points on two opposite sides, typically the longer sides, which allow for easy access and handling with forklifts, pallet jacks, or conveyor systems.

Lightweight: Plastic pallets are generally lighter than wooden counterparts, making them easier to handle and more cost-effective to transport. Their lightweight nature contributes to reduced shipping costs and increased efficiency.

Safety: These pallets are designed with rounded edges and smooth surfaces to minimize the risk of injuries to workers and damage to goods during handling.

WHAT YOU ARE CONCERNED ABOUT: In general, what are the differences between the two raw materials used to make plastic pallets?

The raw materials for making plastic pallets are generally PP (polypropylene) and PE (polyethylene), as well as some auxiliary additives. Generally, plastic pallets made of PP have better heat resistance than those made of PE materials. Generally speaking, the melting point temperature of PP is higher than that of PE materials, which can reach 167 degrees Celsius. Plastic pallets made of PP material can withstand high temperatures of about 95 degrees Celsius and will not deform at 150 degrees Celsius without external force. Therefore, plastic pallets made of pp are very suitable for operations in high temperature environments (not exceeding 95 degrees Celsius). The high temperature resistance of PE material is not as good as that of PP material. Its melting point is less than 130 degrees Celsius, about 95-105 degrees Celsius. Plastic pallets made with it can only withstand up to 65-75 degrees Celsius.

The low temperature resistance of PE is better than that of PP. The low temperature resistance can reach -70 degrees Celsius to -100 degrees Celsius, while PP does not have such excellent low temperature resistance. If we need to use plastic pallets in low temperature environments, it is recommended that you choose plastic pallets made of PE material. For example, in some food processing plants, a lot of food needs to be stored in cold storage, and the temperature of the cold storage is generally relatively low, which requires that the plastic pallets, plastic turnover boxes and other storage equipment we use must be relatively low-temperature resistant. of. The low temperature resistance of PP is weaker than that of PE. The molecular structure of PP is very similar to that of PE. They can both be oxidized and degraded under the action of ultraviolet rays and heat energy.